Tool Steels

Tool and Die Steel Includes Cold Work Steel, Hot Work Steel, Plastic Mould Steel, High Speed Steel. These tool materials adhere to great quality demands of steel like temper, strength, toughness, resistance to tempering, hardening capacity, dimensional stability etc. The range of Tool Steel in our store includes products from renowned manufacturers.

Main characteristics and applications

Pre-hardened Sulphur alloyed plastic mold steel with excellent machinability, also in hardened and tempered condition, thanks to the Manganese-sulfide.

The main application is for core-parts and underbodies of plastic moulds also in large sizes; steel not to be used for polishing and texturing.

It is also used for plates, mould frames, die boxes. It is suitable for nitriding (around 800 HV).

Comparable standards

| DIN | W.Nr | AFNOR |

|---|---|---|

| 40CrMnMoS8-6 | 1.2312 | 40CMD8 |

Chemical composition (typical; in weight %)

| C | Si | Mn | P (max) | S (max) | Cr | Mo |

|---|---|---|---|---|---|---|

| 0.35-0.45 | 0.30-0.50 | 1.40-1.60 | 0.03 | 0.03 | 1.80-2.00 | 0.15-0.25 |

Critical points

Ac1 740 °C

Ac3 820 °C

Ms 310 °C

Production technology

EAF – LF – VD - Forging – Heat treatment QT

US specification

In according to standard EN10228-3 Class 4 and standard SEP 1921 Class E/e

Delivery condition

WW.NR. 1.2312 is delivered in quenched and tempered condition, with hardness range 270 - 310 HB (28 - 33 HRC).

Physical properties (reference values)

| 20°C | 100°C | 250°C | 500°C | |

|---|---|---|---|---|

| Thermal expansion coefficient (10-6/K) | 12.1 | 12.4 | 12.9 | 13.9 |

| Thermal conductivity (W/mk) | 38.9 | 39 | 40.1 | 35.7 |

| Young modulus (Kn/mm2) | 212 | 205 | 200 | 175 |

Heat treatment

| TREATMENT | TEMPERA TURE | HOLDING TIME (HT) | COOLING | COMMENTS | |

|---|---|---|---|---|---|

| Annealing | Heat to 700 - 720 °C | Min. H.T. for 2 minute /mm | Air or furnace | In order to obtain hardness lower than 250 HB ( 24 HRC) to improve machinability | |

| Stress relieving | Heat to 560 - 600 °C (max 30 °C below tempering temperature) | Min. H.T. for 2 minute /mm | Air or furnace | To be carried out after machining, is recommended to eliminate the residual stresses induced by mechanical working | |

| Hardening | Heat to 860-880°C | Min. H.T. for 1 minute /mm | Polymer | - | |

| Tempering | In the range 550 – 620°C | Min. H.T. for 3 minute /mm | Air or furnace | To be carried out after hardening. 2nd Tempering must be performed to max 30°C below tempering temperature | |

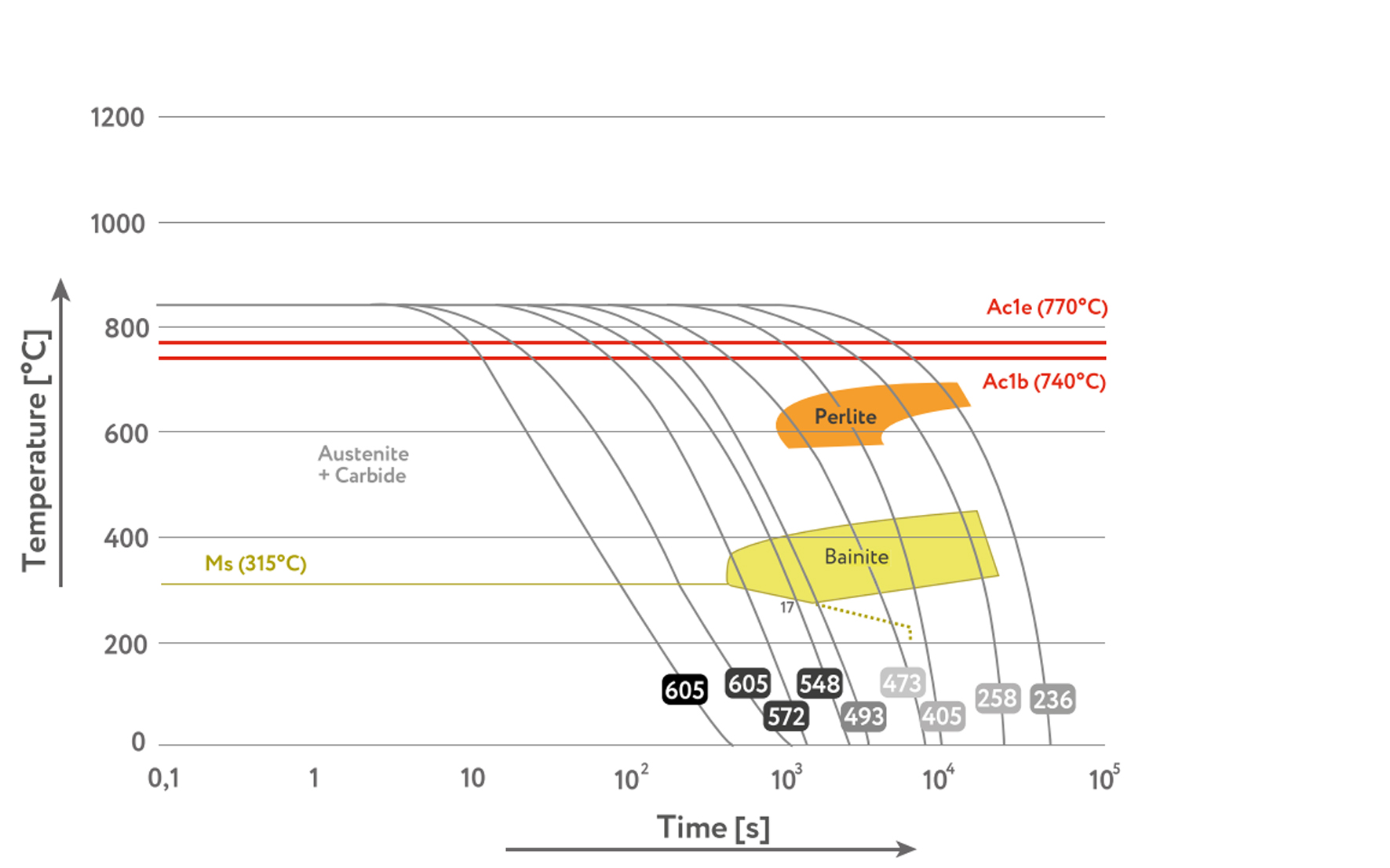

C.C.T. curve

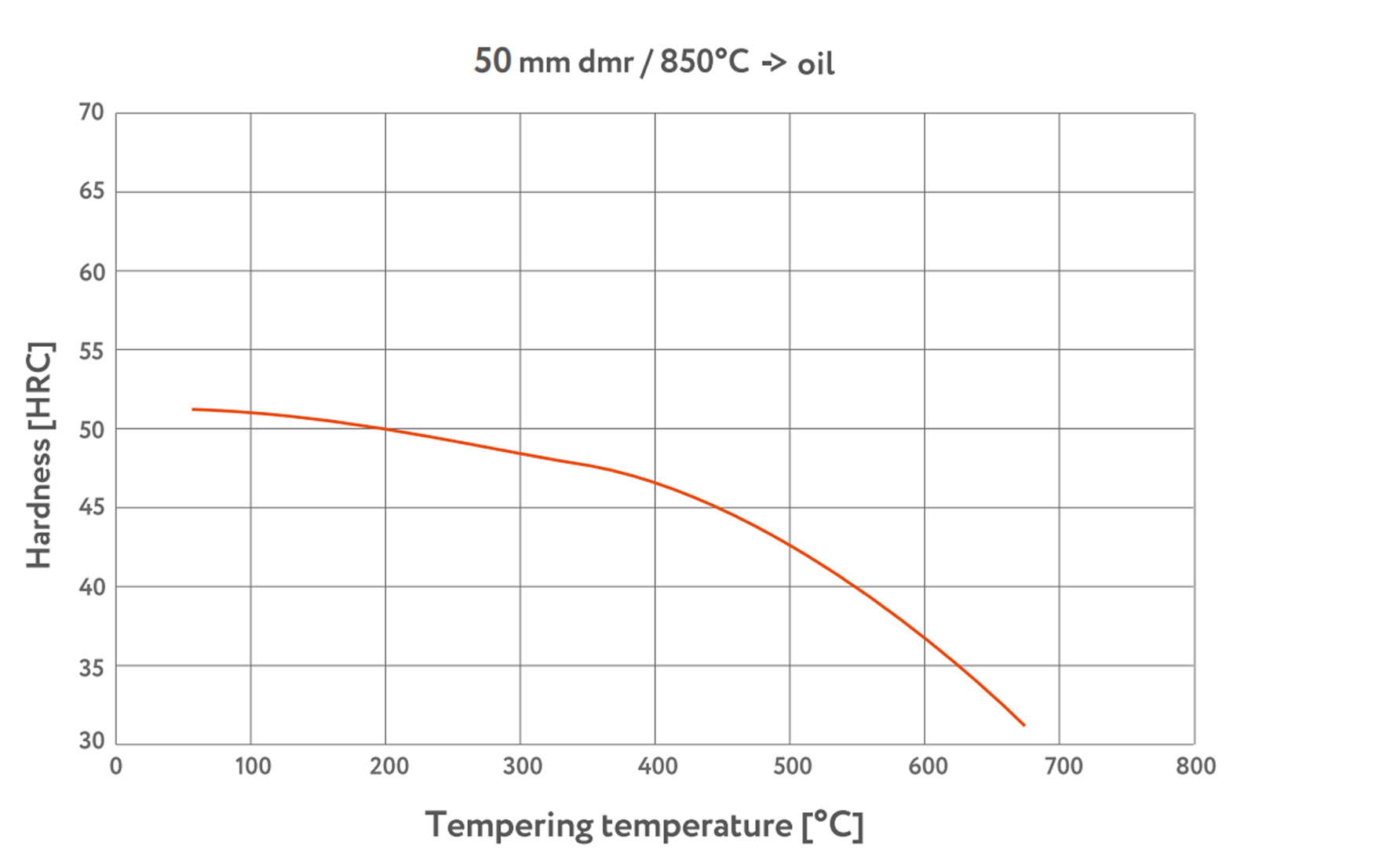

Tempering curve

English

English Czech

Czech German

German