Tool Steels

Tool and Die Steel Includes Cold Work Steel, Hot Work Steel, Plastic Mould Steel, High Speed Steel. These tool materials adhere to great quality demands of steel like temper, strength, toughness, resistance to tempering, hardening capacity, dimensional stability etc. The range of Tool Steel in our store includes products from renowned manufacturers.

Main characteristics and applications

Medium alloyed cold work steel with good hardening capacity, high wear resistance, dimensionally stable during heat treatment. Its applications are small tools for cutting and punching, shear knives, thread rolling tools, measuring tools, wood working tools.

Comparable standards

| DIN | W.Nr | AFNOR | AISI/ASIM | JIS |

|---|---|---|---|---|

| 100MnCrW4 | 1.2510 | 95MnWCr5 | O-1 | SKS3 |

Chemical composition (typical; in weight %)

| C | Si | Mn | P (max) | S (max) | Cr | W | V |

|---|---|---|---|---|---|---|---|

| 0.90-1.05 | 0.15-0.35 | 1.00-1.20 | 0.035 | 0.035 | 0.50-0.70 | 0.50-0.70 | 0.05-0.15 |

Critical points

Ac1 740 °C

Ac3 770 °C

Ms 215 °C

Production technology

EAF – LF – VD - Forging – Heat treatment +A

US specification

In according to standard EN10228-3 Class 4 and standard SEP 1921 Class E/e

Delivery condition

WW.NR. 1.2510 is delivered in annealed condition, with hardness max 230 HB (21 HRC).

Physical properties (reference values)

| 20°C | 100°C | 250°C | 500°C | |

|---|---|---|---|---|

| Thermal expansion coefficient (10-6/K) | 11.4 | 11.7 | 12 | 12.7 |

| Thermal conductivity (W/mk) | 29.9 | 30.1 | 31.7 | 31.2 |

| Young modulus (Kn/mm2) | 212 | 209 | 200 | 175 |

Heat treatment

| TREATMENT | TEMPERATURE | HOLDING TIME (HT) | COOLING | COMMENTS | |

|---|---|---|---|---|---|

| Annealing | Heat to 700 - 720 °C | Min. H.T. for 2 minute /mm | Furnace to 600°C than in air | - | |

| Stress relieving | Heat to 600 - 650 °C | Min. H.T. for 2 minute /mm | Air or furnace | - | |

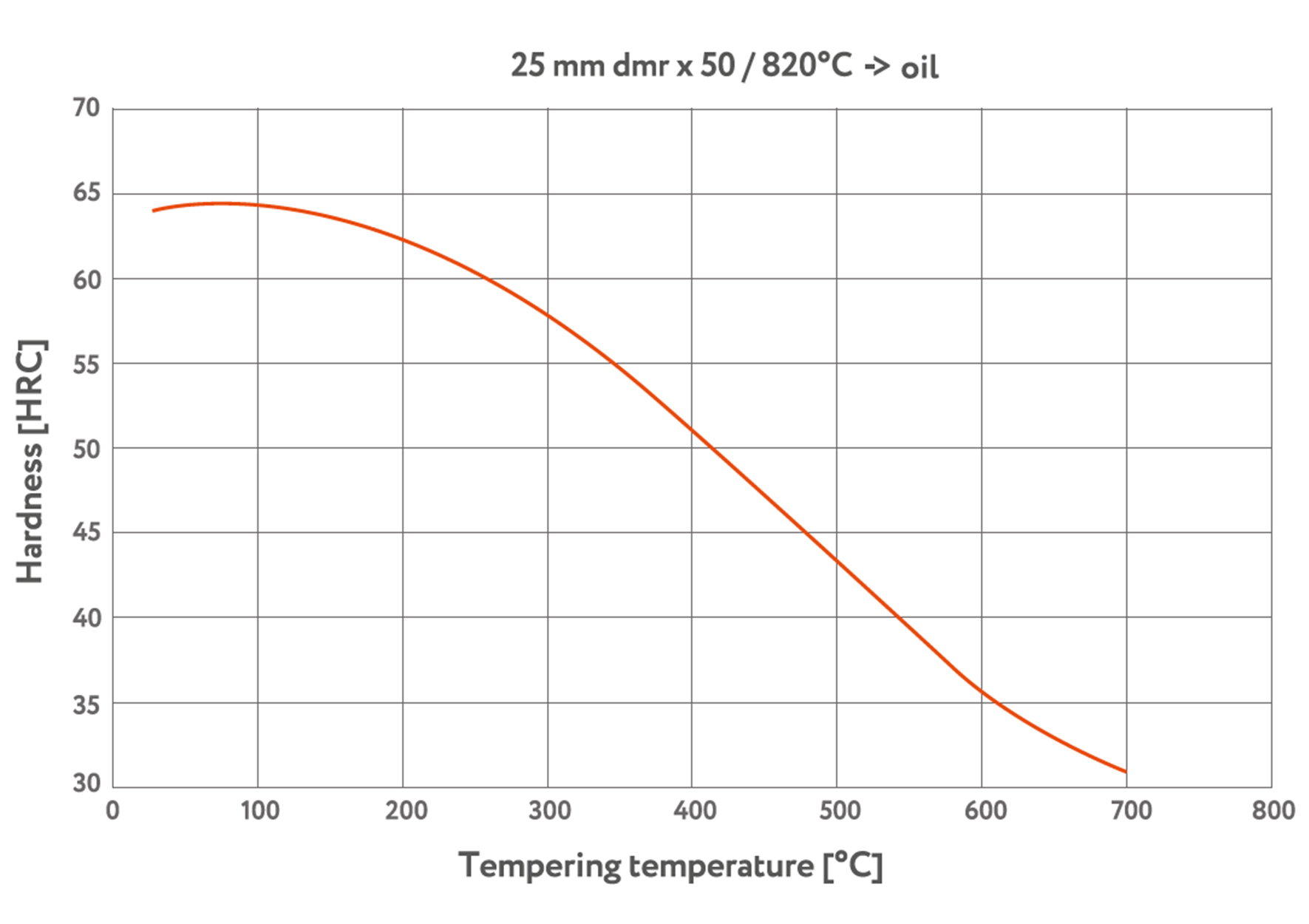

| Hardening | Heat to 790-820 °C | Min. H.T. for 1 minute /mm | Oil or pressure gas (vacuum) | - | |

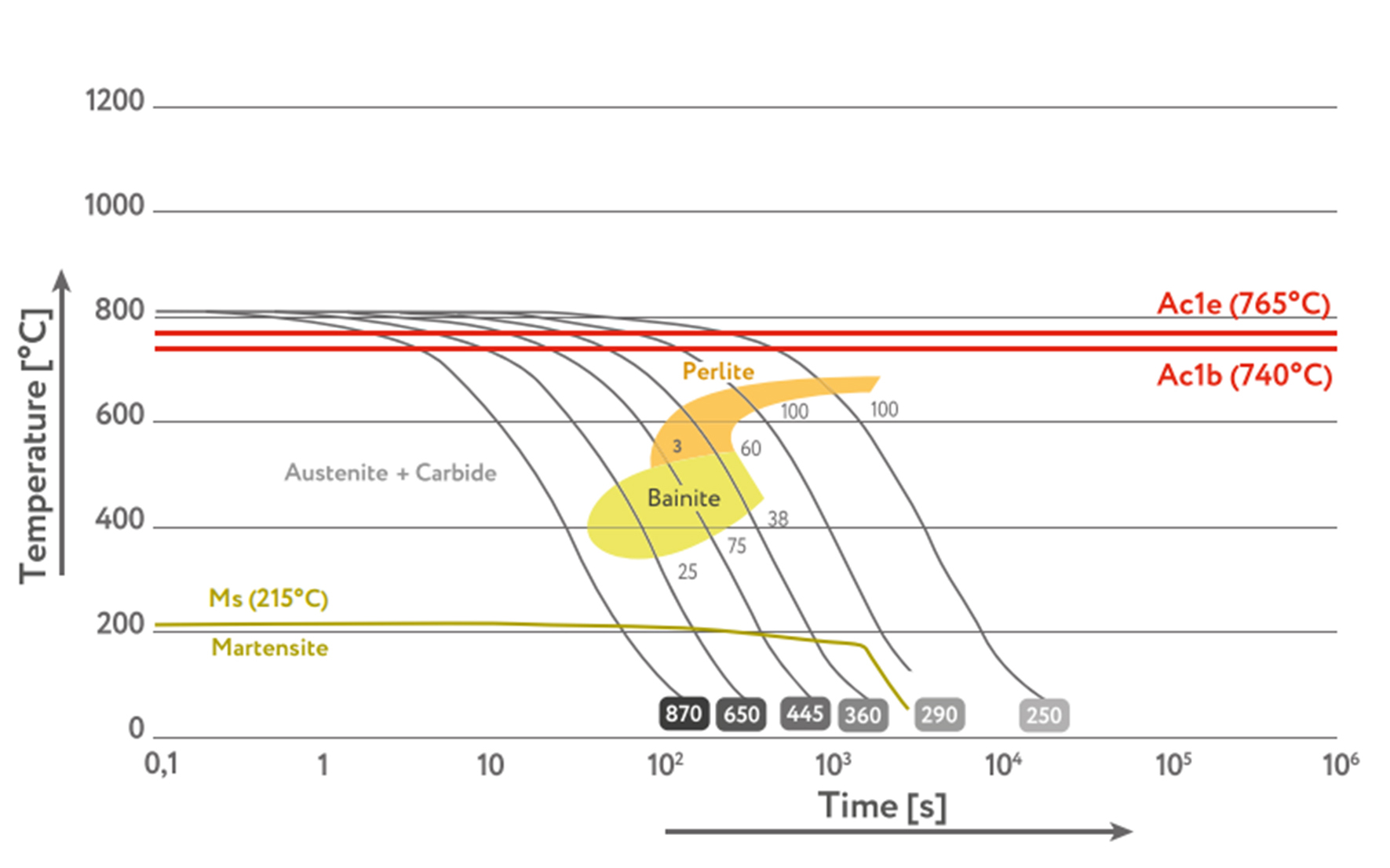

C.C.T. curve

Tempering curve

English

English Czech

Czech German

German