Tool Steels

Tool and Die Steel Includes Cold Work Steel, Hot Work Steel, Plastic Mould Steel, High Speed Steel. These tool materials adhere to great quality demands of steel like temper, strength, toughness, resistance to tempering, hardening capacity, dimensional stability etc. The range of Tool Steel in our store includes products from renowned manufacturers.

Main characteristics and applications

Martensitic stainless steel with a high hardenability, good polishing properties, excellent resistance to corrosion and rust.

Its applications are plastic moulds, high wear resistance cavities particularly for processing of acid aggressive plastics (i.e. acetate and PVC), or plastics containing abrasive fillers. Suited for the manufacture of transparent plastics such as moulds for optical and medical products.

Comparable standards

| DIN | W.Nr | JIS |

|---|---|---|

| X42Cr13 | 1.2083 | SUS420F |

Chemical composition (typical; in weight %)

| C | Si | Mn | P (max) | S (max) | Cr |

|---|---|---|---|---|---|

| 0.38-0.45 | <1.00 | <1.00 | 0.03 | 0.03 | 12.50-14.50 |

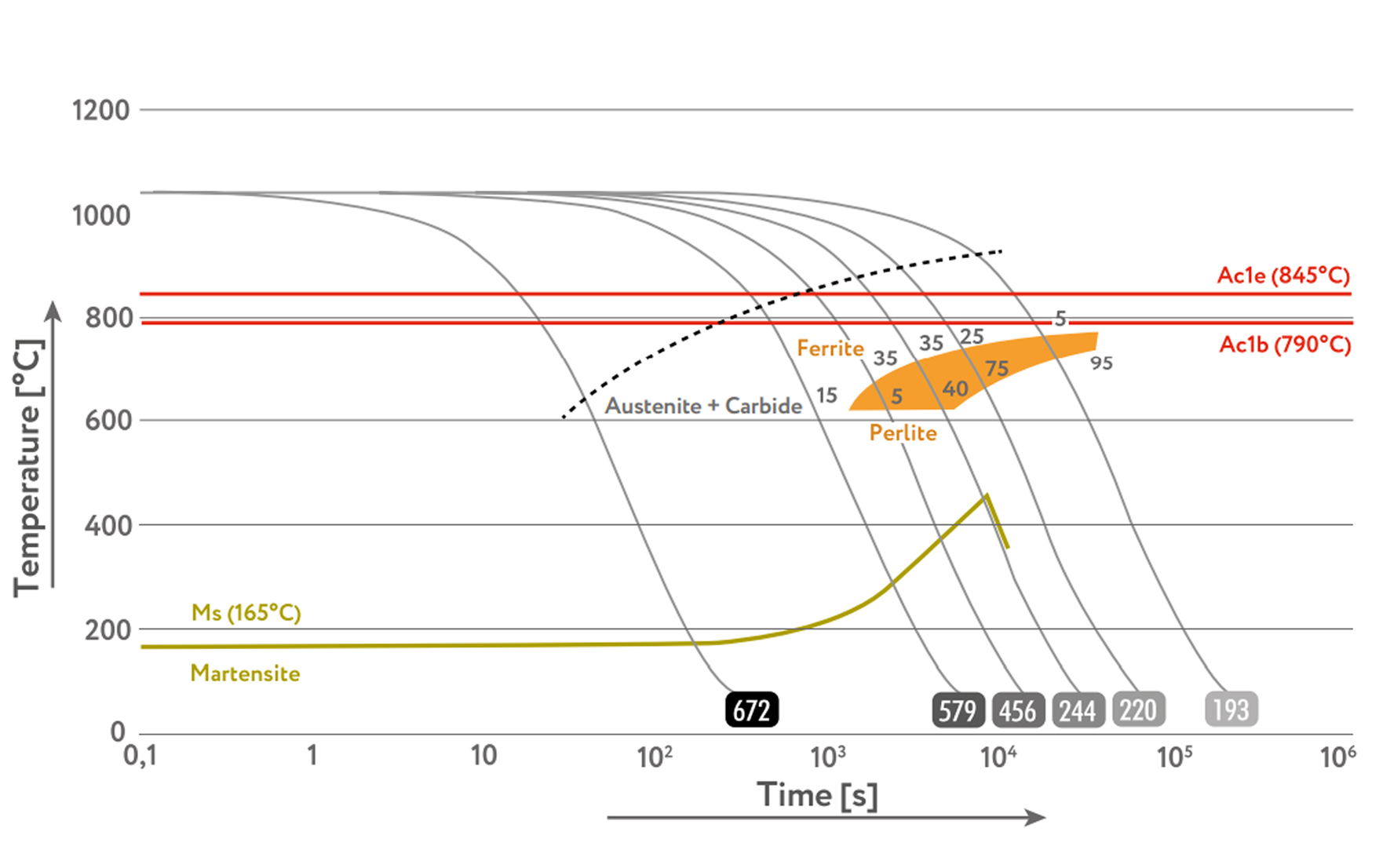

Critical points

Ac1 790 °C

Ac3 850 °C

Ms 165 °C

Production technology

EAF – LF – VD - Forging – Heat treatment +A

US specification

In according to standard EN10228-3 Class 4 and standard SEP 1921 Class E/e

Delivery condition

WW.NR. 1.2083 is delivered annealed condition, with hardness max 241 HB (23 HRC).

Physical properties (reference values)

| 20°C | 100°C | 250°C | 500°C | |

|---|---|---|---|---|

| Thermal expansion coefficient (10-6/K) | 11.1 | 11.4 | 11.8 | 12.6 |

| Thermal conductivity (W/mk) | 20.5 | 22.1 | 23.6 | 25.1 |

| Young modulus (Kn/mm2) | 218 | 210 | 202 | 180 |

Heat treatment

| TREATMENT | TEMPERATURE | HOLDING TIME (HT) | COOLING | COMMENTS | |

|---|---|---|---|---|---|

| Annealing | Heat to 780 - 800 °C | Min. H.T. for 2 minute /mm | Air or furnace | In order to obtain hardness lower than 240 HB ( 23 HRC) to improve machinability | |

| Stress relieving | Heat to 30 °C below tempering temperature | Min. H.T. for 2 minute /mm | Air or furnace | To be carried out after machining, is recommended to eliminate the residual stresses induced by mechanical working | |

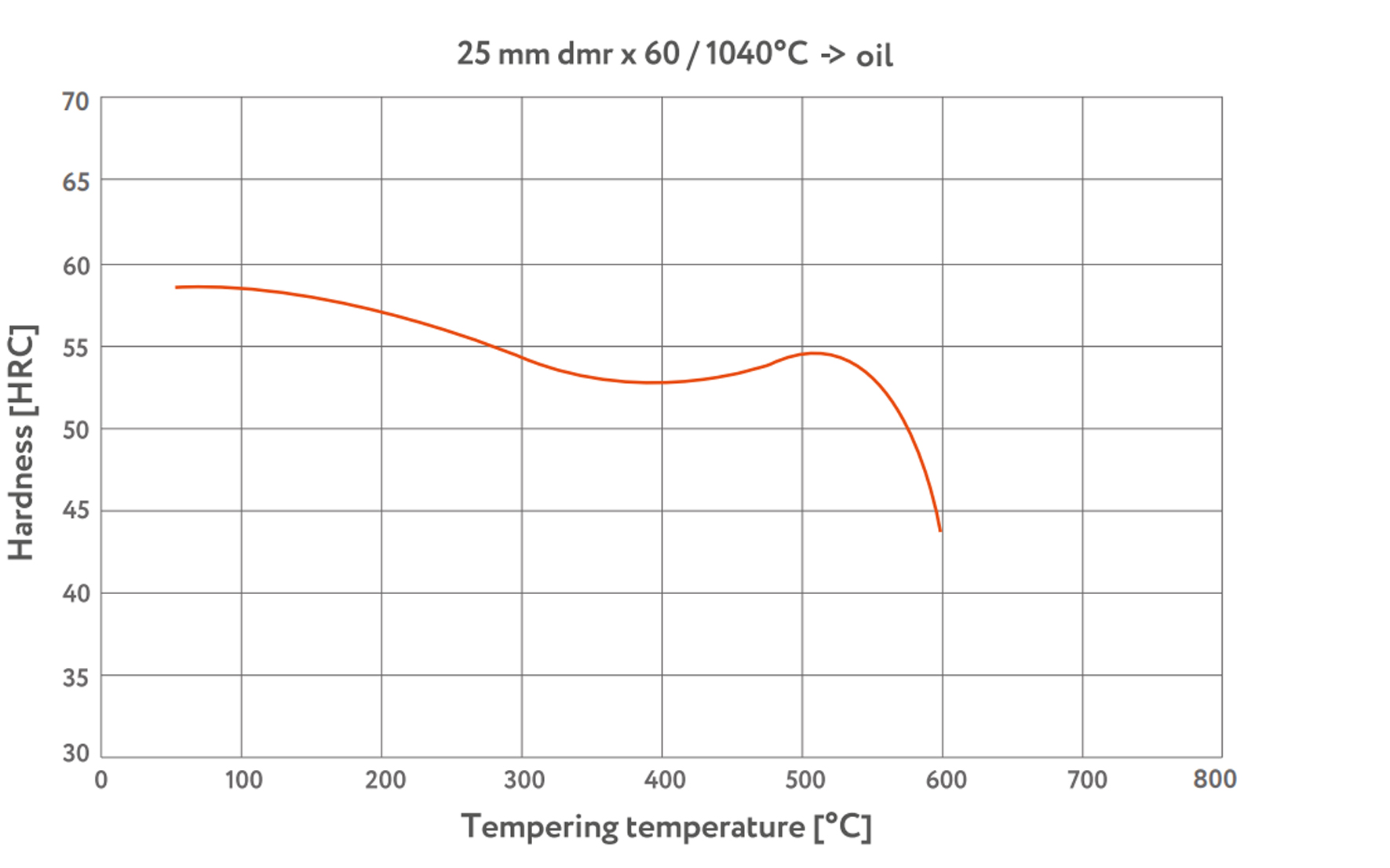

| Hardening | Heat to 1000-1050°C | Min. H.T. for 1 minute /mm | Oil – Gas air | - | |

| Tempering | Heat to 170 – 270°C | Min. H.T. for 3 minute /mm | Air or furnace | To be carried out soon after the hardening according to the required hardness; at 170 – 270°C in order to match hardness and resistance to corrosion; permanence for at least 2 hours; tempering must be repeated at least twice at a temperature 30°C lower than the previous | |

C.C.T. curve

Tempering curve

English

English Czech

Czech German

German