Tool Steels

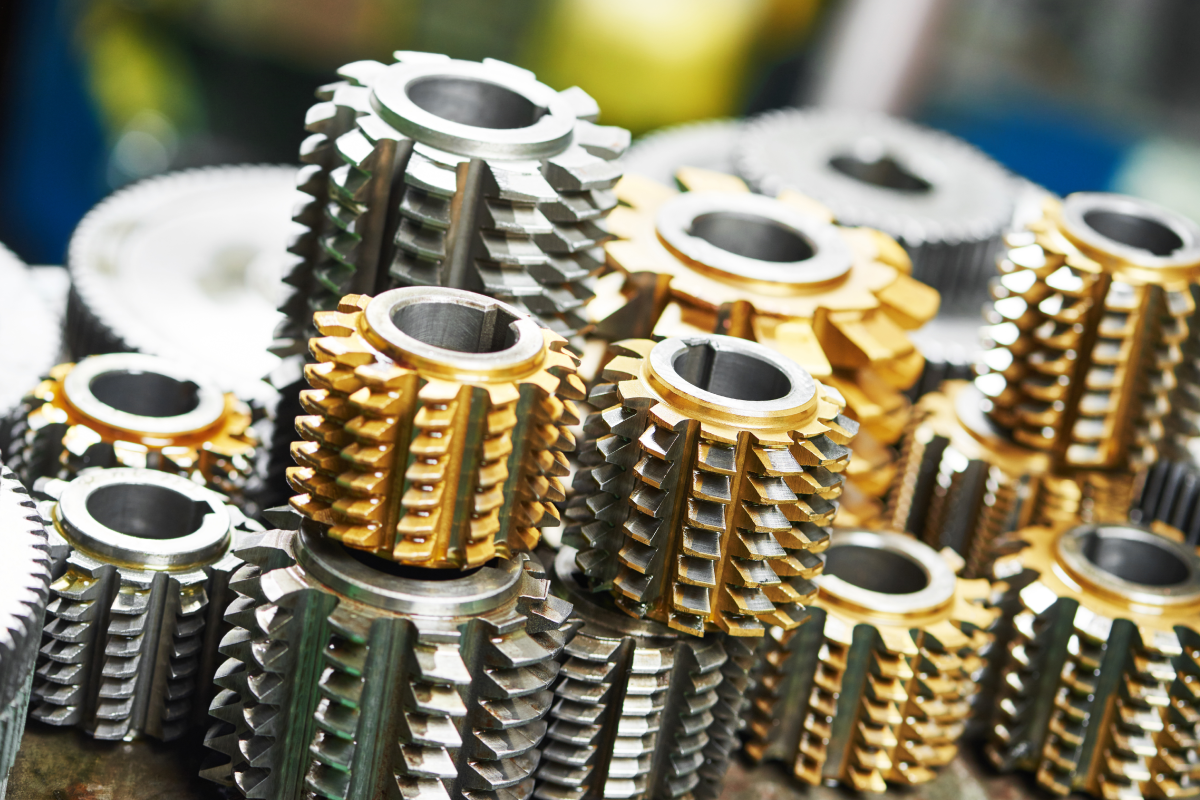

Tool and Die Steel Includes Cold Work Steel, Hot Work Steel, Plastic Mould Steel, High Speed Steel. These tool materials adhere to great quality demands of steel like temper, strength, toughness, resistance to tempering, hardening capacity, dimensional stability etc. The range of Tool Steel in our store includes products from renowned manufacturers.

Main characteristics and applications

Heavy-duty milling cutters of all kinds, highly stressed twist drills and taps, profile knives, machining of high-strength materials, broaches.

Comparable standards

| DIN | W.Nr | AFNOR | AISI/ASIM | JIS |

|---|---|---|---|---|

| S 6-5-2-5 | 1.3243 | Z85WDKCV06-05-05-04-02 | M-35 | SKH55 |

Chemical composition (typical; in weight %)

| C | Si (max) | Mn (max) | P (max) | S (max) | Co | Cr | Mo | V | W |

|---|---|---|---|---|---|---|---|---|---|

| 0.87-0.95 | <0.45 | <0.40 | 0.03 | 0.03 | 4.50-5.00 | 3.80-4.50 | 4.70-5.20 | 1.70-2.10 | 5.90-6.70 |

Steel properties

The cobalt content in this high-performance high-speed steel results in high red hardness and tempering resistance. As a consequence, this grade is particularly suitable for conditions involving thermal stresses and discontinuous cutting. Under the name Rapidur 3245, AISI M 35 + S and material number 1.3245, this steel grade is supplied with a higher sulphur content (S = 0.10 %).

Heat treatment

| TREATMENT | TEMPERATURE | COOLING | HARDNESS | |||

|---|---|---|---|---|---|---|

| Annealing | Heat to 770 – 860 °C | Furnace | max. 269 | |||

| Stress-relief annealing °C | Heat to 630 – 650 °C | Furnace | - | |||

| 1st pre-heating °C | 2nd and 3rd pre-heating °C | Hardening1 °C | Quenching | Tempering °C | Quenching | |

| up to approx. 400 in an air-circulating furnace | a) 850 | 1190 – 1230 | a) Saltbath, 550 °C | at least twice 530 – 560 | 64 – 67 | |

| - | b) 850 and 1050 | - | b) Oil | - | - | |

| - | - | - | c) Air | - | - | |

For cold-forming tools with a complex geometry, a hardening temperature at the lower end of the quoted range is recommended. The stated hardening temperatures apply to saltbath hardening only. For vacuum hardening, we suggest a reduction of 10 °C to 30 °C.

English

English Czech

Czech German

German