Tool Steels

Tool and Die Steel Includes Cold Work Steel, Hot Work Steel, Plastic Mould Steel, High Speed Steel. These tool materials adhere to great quality demands of steel like temper, strength, toughness, resistance to tempering, hardening capacity, dimensional stability etc. The range of Tool Steel in our store includes products from renowned manufacturers.

Main characteristics and applications

Hot working special steel with high wear resistance associated with special thermal fatigue properties.

Steel can be air hardened or pressure gas (vacuum) which makes it possible to reduce distortion and cracks caused by heat treatment.

At working hardness of 50HRC excellent toughness and is therefore suitable for use in a wide field of operating condition.

This steel is used for tools as:

• dies for the pressure casting of light alloys.

• wear resistance moulds for plastic processing.

• dies for friction and mechanical presses for hot forming of steel, brass, aluminum and its alloys.

• extrusion dies for aluminum processing.

• hot work shear blades.

To raise lifetime of tools this steel can be submitted to surface treatment as thermo-chemical treatments on the tools or nitriding (ion – saline – gaseous).

Comparable standards

| DIN | W.Nr | AFNOR | AISI/ASIM | JIS |

|---|---|---|---|---|

| X38CrMov5-1 | 1.2343 | Z38CDV5 | H-11 | SKD6 |

Chemical composition (typical; in weight %)

| C | Si | Mn | P (max) | S (max) | Cr | Mo | V |

|---|---|---|---|---|---|---|---|

| 0.33-0.41 | 0.80-1.20 | 0.25-0.50 | 0.03 | 0.03 | 4.80-5.50 | 1.10-1.50 | 0.30-0.50 |

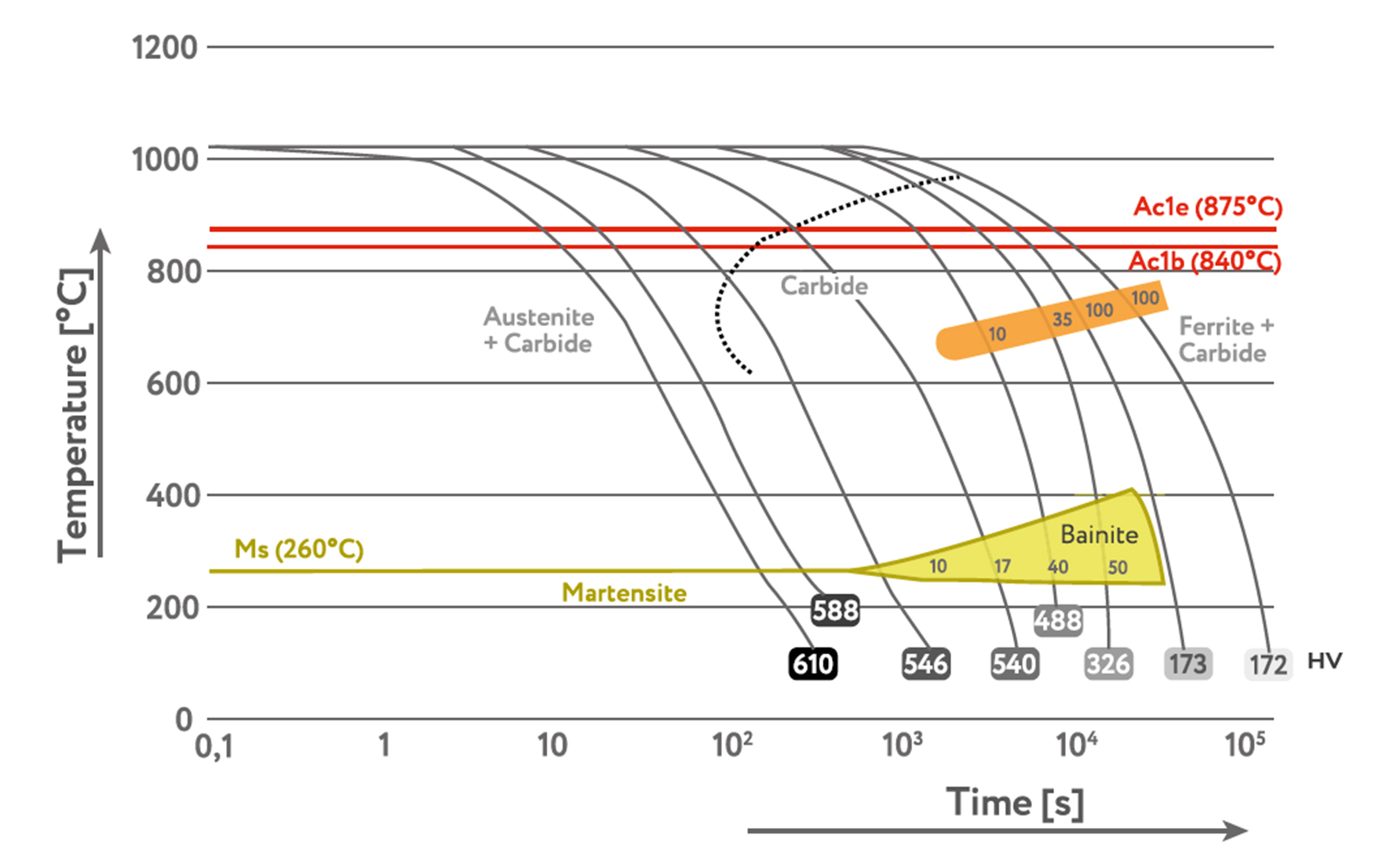

Critical points

Ac1 840 °C

Ac3 880 °C

Ms 260 °C

Production technology

EAF – LF – VD - Forging – Heat treatment +EF

US specification

In according to standard EN10228-3 Class 4 and standard SEP 1921 Class E/e

Delivery condition

WW.NR. 1.2343 is delivered in annealed condition (EFS), with hardness max 230 HB (21 HRC)

Physical properties (reference values)

| 20°C | 100°C | 250°C | 500°C | |

|---|---|---|---|---|

| Thermal expansion coefficient (10-6/K) | 11.3 | 11.7 | 12.1 | 13.2 |

| Thermal conductivity (W/mk) | 18.8 | 19 | 22.9 | 24.9 |

| Young modulus (Kn/mm2) | 212 | 209 | 197 | 175 |

Heat treatment

| TREATMENT | TEMPERATURE | HOLDING TIME (HT) | COOLING | COMMENTS | |

|---|---|---|---|---|---|

| Annealing | Heat to 850 °C | Min. H.T. for 2 minute /mm | Furnace up to 550°C than in air | - | |

| Stress relieving | Heat to 650-700°C | Min. H.T. for 2 minute /mm | furnace up to 300-350°C | To be carried out after machining, is recommended to eliminate the residual stresses induced by mechanical working | |

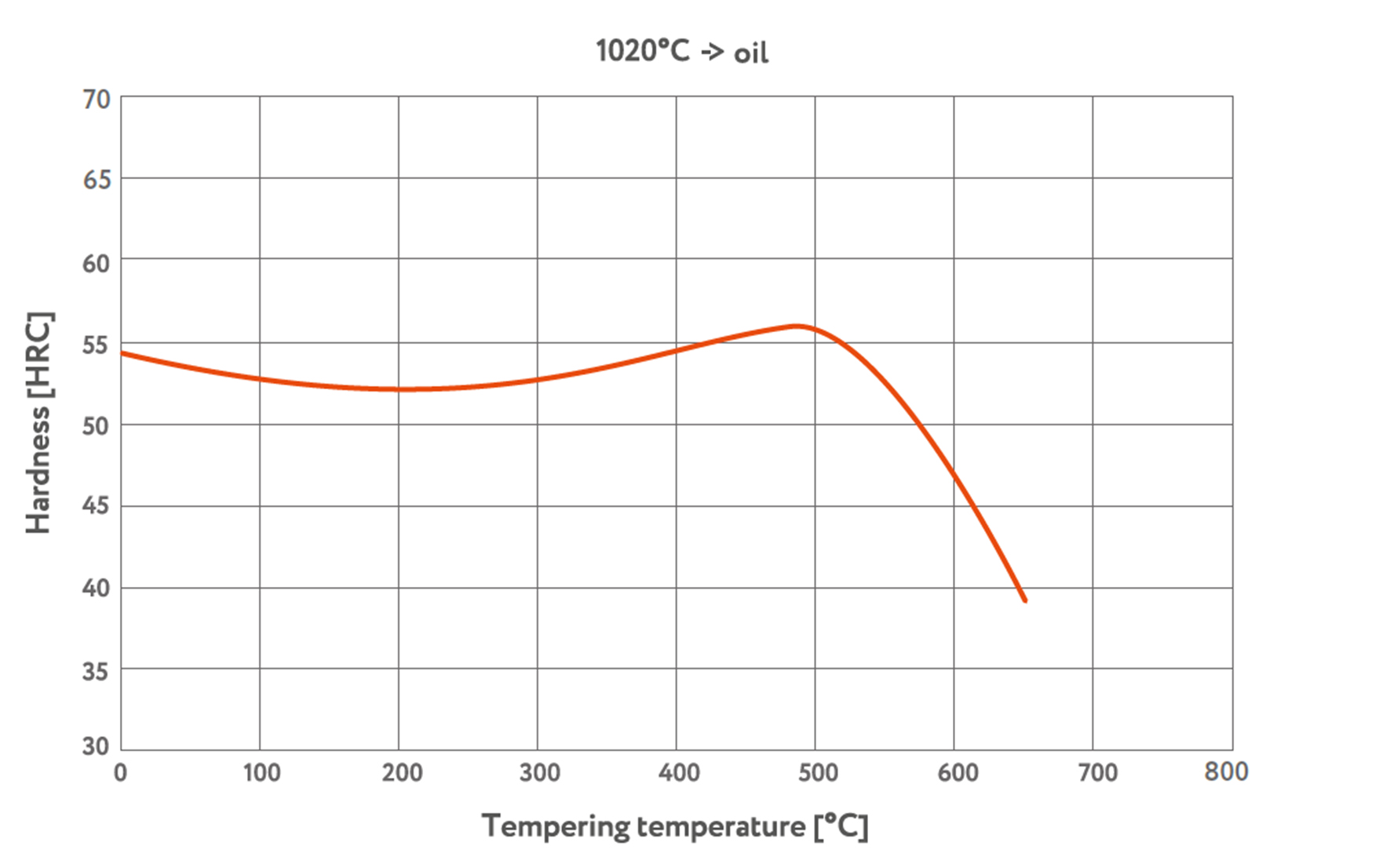

| Hardening | Preheating to 350-400°C Second preheating to 750-850°C Heat to hardening temperature to 1000-1020°C | Min. H.T. for 1 minute /mm | Air or pressure gas by vacuum | Quenched hardness 52-56HRC | |

| Tempering | In the range 550 – 600°C for at least 3 h according to hardness requirements and conditions of use. Tempering must be repeated a second time at a temperature equal to or 20°C lower than the previous. Before tempering, the parts must be preheated to 200 – 300°C | Air | Usual service hardness: 48-52 HRC | ||

C.C.T. curve

Tempering curve

English

English Czech

Czech German

German